PRODUCTS |

Product Details

Home>

Product Details

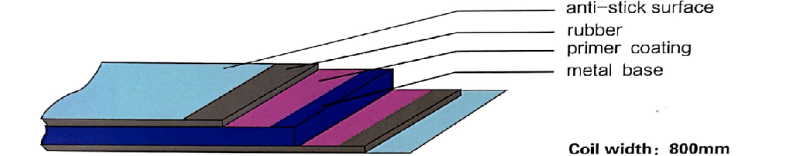

I. Construction

II. Application Shock absorption shim, noise damping shim, vibration damper for bake system, spring accessories etc.

III. Characteristics: High adhesive force of the rubber coating and suitable for high temperature environmental and fluids including engine oil, anti-freezer and coolant etc. A flat & smooth surface; Corrosion resistance ; Fine shock damping and noise absorption effect; IV. Specifications

Key points for affixing cold adhesive kind of brake shim: 1.Grease of the bonded areas shall be cleaned; 2.Recommend hot press to ensure being pressurized evenly; 3.Such things might happen including no bonding and twisting caused by operational environmental difference. So, mechanical fastening is recommended if necessary. 4.The released paper of the PSA shall be firstly removed before assembling the brake pad.

Previous: Rubber coated metal for Gaskets

Next: No information found

|